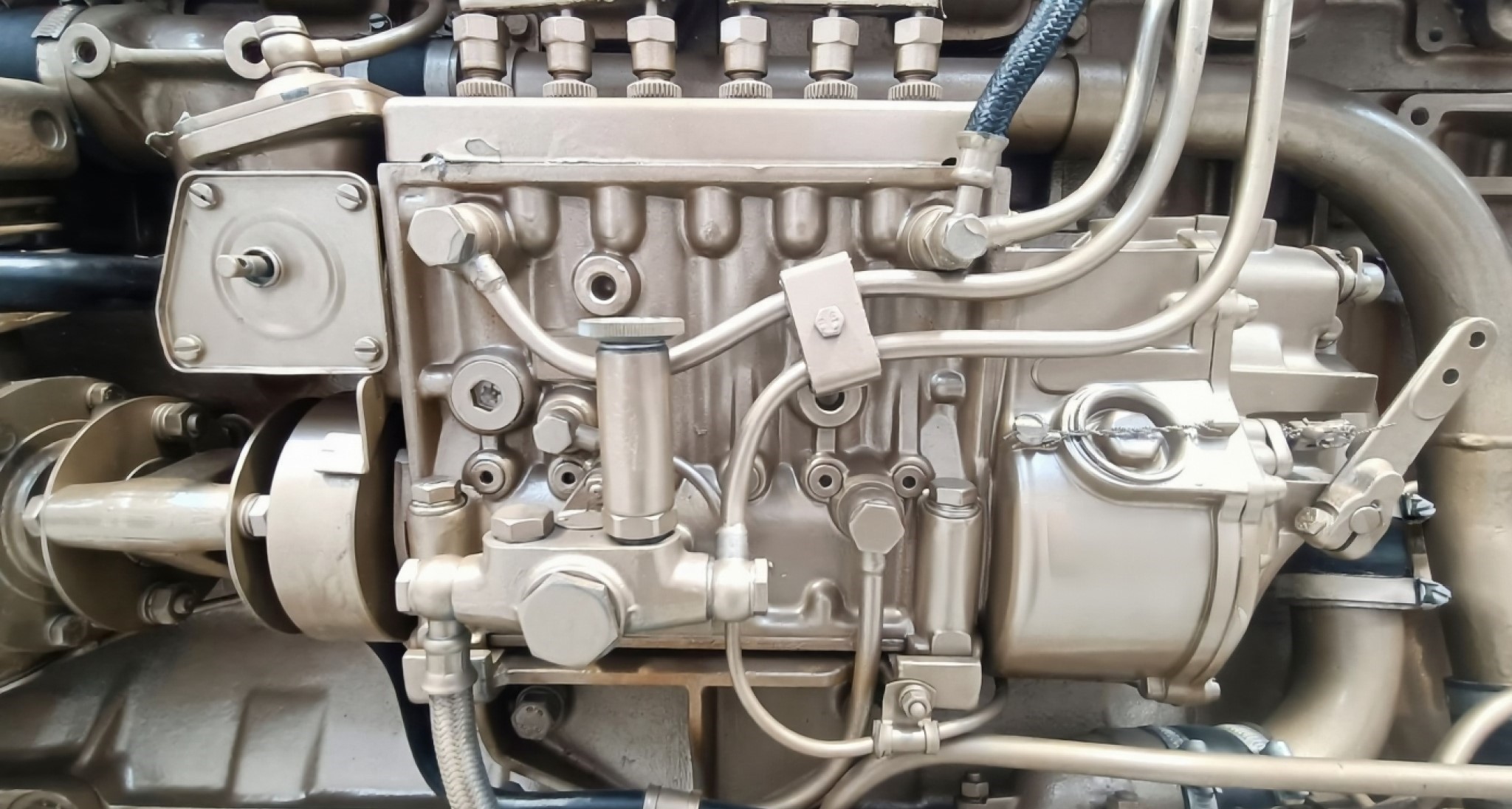

Diesel injector pumps are the heart of your engine’s fuel system. When they fail, performance drops, fuel economy suffers, and breakdowns become inevitable. In this post, we’ll explore what causes injector pump failures, how to spot the warning signs, and what Torqueline does to restore them to peak condition.

Key Sections:

- What Does a Diesel Injector Pump Do? It pressurizes and delivers fuel to the injectors at precise timing and volume critical for combustion and engine efficiency.

- Common Causes of Failure:

- Wear and tear over time

- Fuel contamination (water, debris, varnish)

- Poor maintenance or skipped service intervals

- Use of low-quality fuel or parts

- Symptoms to Watch For:

- Hard starting or engine won’t start

- Loss of power under load

- Excessive black or white smoke

- Poor fuel economy

- Torqueline’s Repair Process:

- Diagnostic testing of fuel pressure and timing

- Disassembly and inspection

- Ultrasonic cleaning and part replacement

- Calibration and bench testing

Conclusion: Early detection and professional repair can save thousands in downtime and damage. Trust Torqueline to bring your diesel systems back to life.